Product Category

Latest News

- Congratulations for Successful show at 25th Xiamen International Stone Fair

- Join Us at the 2025 Xiamen Stone Fair

- Join Us at Marmomac 2024 in Verona Italy

- How To Choose The Good Diamond Wire for Your Cutting Works?

- Introducing Our New G123 Cobalt-Free Bond Diamond Wire!

- Why Diamond Wire Saw Is Becoming Popular?

- What's the Steps of Using Diamond Wire Saw Correctly

- How to Keep The Wire Saw Machine in Good Condition

- How To Choose Diamond Polishing Pads Correctly

- Diamond Wire for Granite Quarry And Processing Work

- Advantages of Wire Saw Machine Enhancing Efficiency and Precision

- Why Diamond Core Drill Bit Is Popular in Construction Industry?

- What’s The Applications of Diamond Wire Saws?

- Why Use A Diamond Saw Blade?

- WHY USE A DIAMOND WIRE SAW FOR CONCRETE CUTTING?

- What Are The Obvious Advantages of Diamond Wire Sawing

- What’s the applications of diamond wire saw: Granite, Marble or Concrete?

- How to use diamond wire saw correctly?

- What are Diamond Drill Bits used for?

- What is a diamond tool?

Related Products

Vulcanized Rubber Diamond Wire Saw for Granite Sandstone Quartzite Quarry

| Availability: | |

|---|---|

| Quantity: | |

-

W789-72

-

KEENTOOL

-

82029910

Vulcanized rubber diamond wire saw is suitable for cutting banks of any size effectively and safely and slabbing them into blocks.

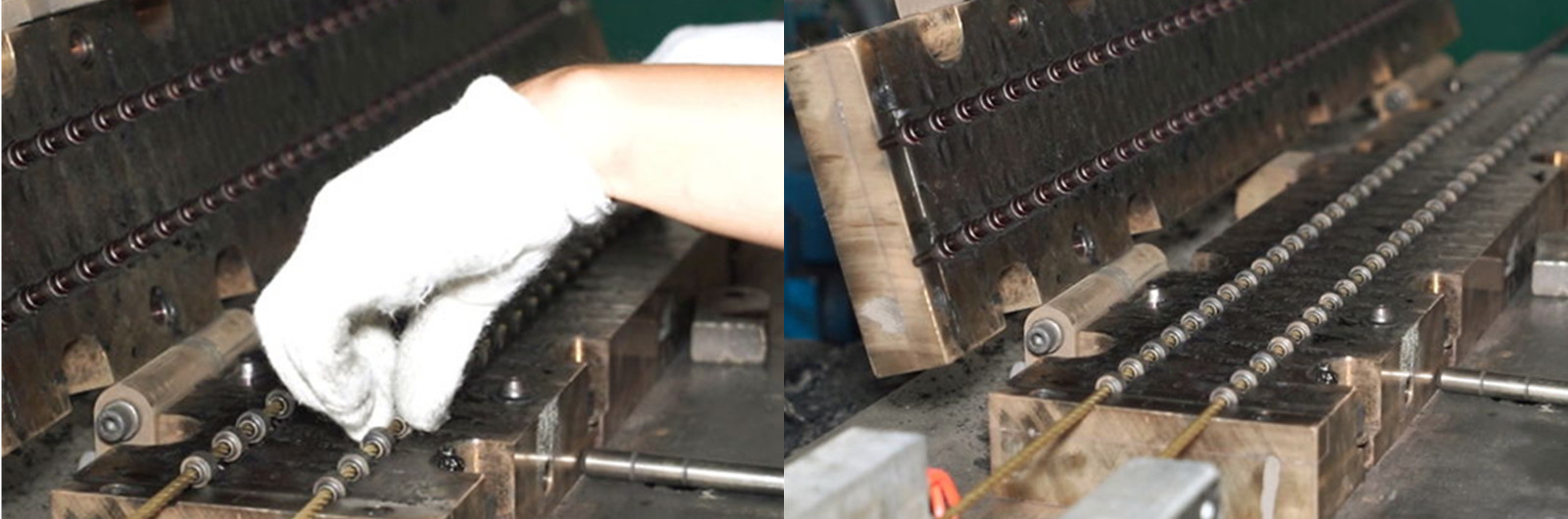

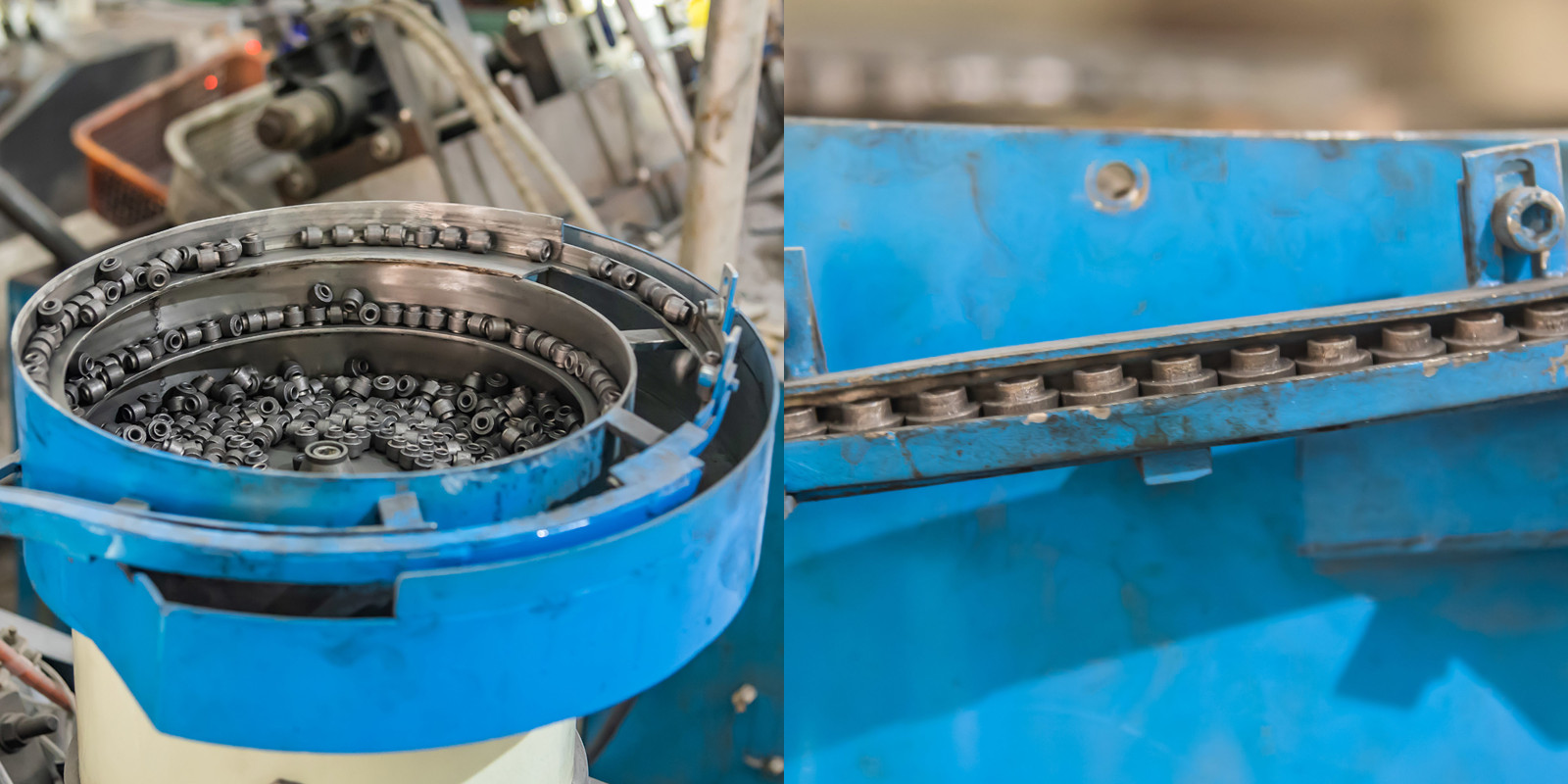

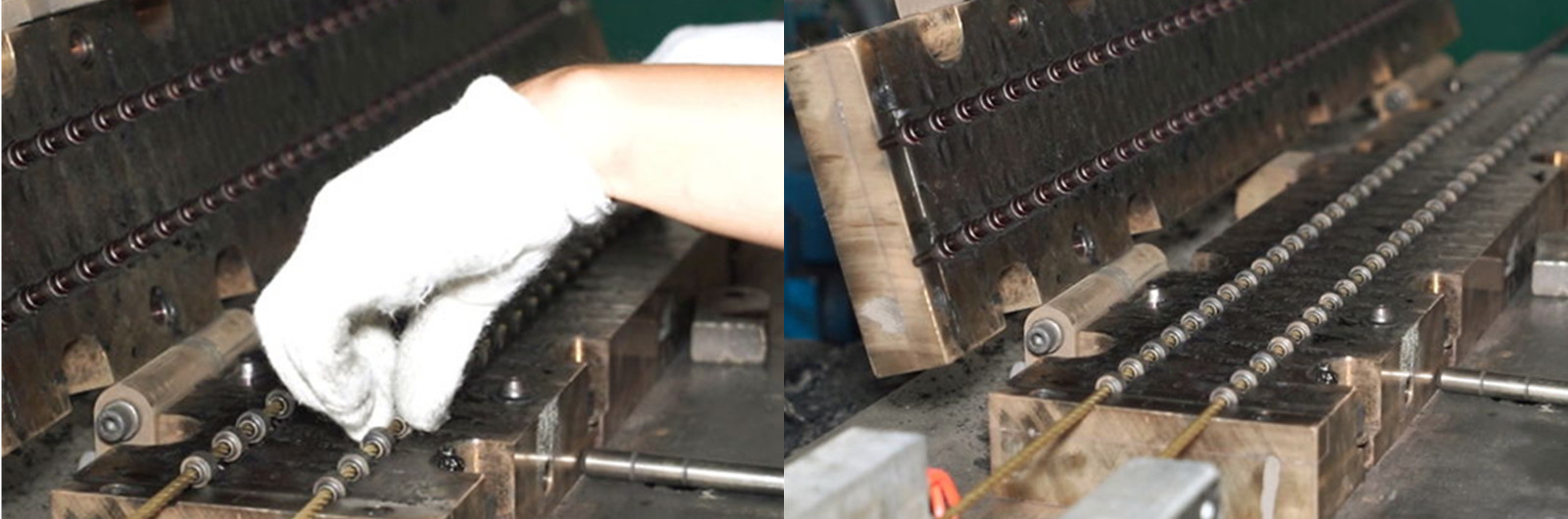

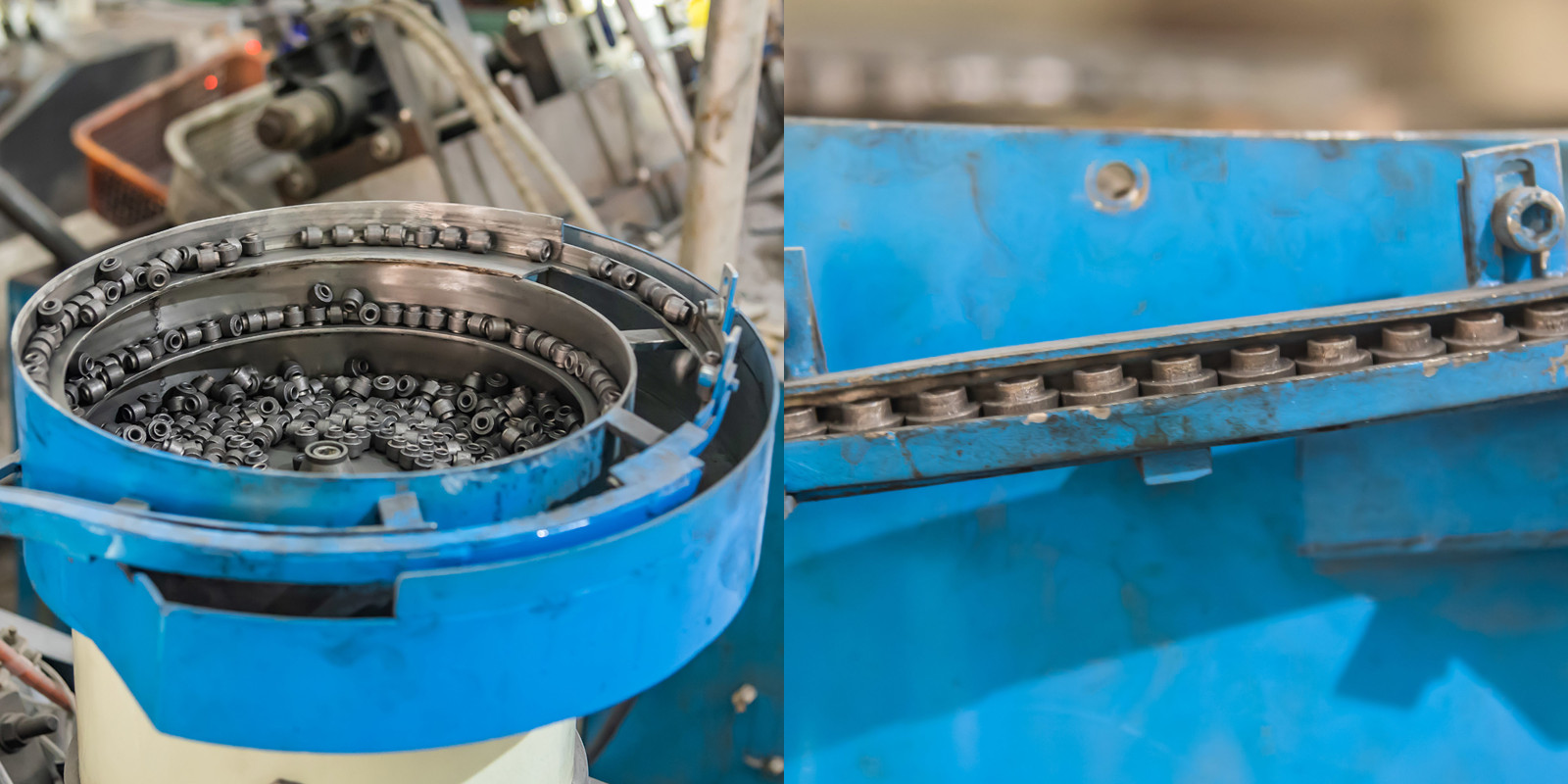

We produce the diamond wire saw with procedures as follows:

1. Sintered diamond beads with cobalt bond system and top quality diamond from South Korea and U. K.

2. 40PCS diamond beads with diameter of 11.5mm , and 6.5mm width of diamond for better cutting life.

3. Top quality steel cable from Germany with diameter of 4.8mm and structure of 133 thighs(7*19PcS).

4. Good quality crude rubber with advanced technical procedures and equipment for injection.

APPLICATIONS | Art No | Specification (mm) | Beads/M | Reinforcement |

For cutting Granite, Quartzite, Sandstone Hard&Abrasive stone in quarry | W789-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber |

G623A-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber | |

G635A-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber | |

G635B-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber | |

Cutting Material | Linear Speed (M/S) | Cutting Speed (M2/H) | Cutting Life (M2/M) | |

Soft | 28-35 | 8-15 | 25-35 | |

Medium | 28-35 | 8-10 | 20-28 | |

Hard&Abrasive | 26-32 | 6-8 | 12-18 | |

SPECIFICATION OF BEADS | Out Diameter | Length of work layer (mm) | Bead Length | Manufacture Tech |

¢11.5 | 6.5 | 11 | Sintered | |

¢11.0 | 6.5 | 11 | Sintered |

Above mentioned diamond wire saw we currently supply in different quarries. have achieved consistent performanceand a balance of wire life to suit the customers requirements.

▲1.Soft Granite Class I-ll (Abrasive/ Non-abrasive)- Quarry cutting: Achieving 10 to 15 square meters per hour and

32-35 square meters per linear meter of wire life on 37 on 55kw wire saw machines.

▲2.Medium hard Granite Class III-IV(abrasive)- Quarry cutting: Achieving 8 to 12 square meters per hour and 22-25square meters per linear meter of wire life on 55 or75kw wire saw machines.

▲3.Hard Granite Class V (Very Abrasive) - Quarry cutting Achieving: 8 square meters per hour and 14-16 square meters per linear meter of wire on 55 or 75kw wire saw machines.

Vulcanized rubber diamond wire saw is suitable for cutting banks of any size effectively and safely and slabbing them into blocks.

We produce the diamond wire saw with procedures as follows:

1. Sintered diamond beads with cobalt bond system and top quality diamond from South Korea and U. K.

2. 40PCS diamond beads with diameter of 11.5mm , and 6.5mm width of diamond for better cutting life.

3. Top quality steel cable from Germany with diameter of 4.8mm and structure of 133 thighs(7*19PcS).

4. Good quality crude rubber with advanced technical procedures and equipment for injection.

APPLICATIONS | Art No | Specification (mm) | Beads/M | Reinforcement |

For cutting Granite, Quartzite, Sandstone Hard&Abrasive stone in quarry | W789-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber |

G623A-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber | |

G635A-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber | |

G635B-72 | ¢11.5×6.5 | 40/37 | Vulcanized Rubber | |

Cutting Material | Linear Speed (M/S) | Cutting Speed (M2/H) | Cutting Life (M2/M) | |

Soft | 28-35 | 8-15 | 25-35 | |

Medium | 28-35 | 8-10 | 20-28 | |

Hard&Abrasive | 26-32 | 6-8 | 12-18 | |

SPECIFICATION OF BEADS | Out Diameter | Length of work layer (mm) | Bead Length | Manufacture Tech |

¢11.5 | 6.5 | 11 | Sintered | |

¢11.0 | 6.5 | 11 | Sintered |

Above mentioned diamond wire saw we currently supply in different quarries. have achieved consistent performanceand a balance of wire life to suit the customers requirements.

▲1.Soft Granite Class I-ll (Abrasive/ Non-abrasive)- Quarry cutting: Achieving 10 to 15 square meters per hour and

32-35 square meters per linear meter of wire life on 37 on 55kw wire saw machines.

▲2.Medium hard Granite Class III-IV(abrasive)- Quarry cutting: Achieving 8 to 12 square meters per hour and 22-25square meters per linear meter of wire life on 55 or75kw wire saw machines.

▲3.Hard Granite Class V (Very Abrasive) - Quarry cutting Achieving: 8 square meters per hour and 14-16 square meters per linear meter of wire on 55 or 75kw wire saw machines.