Product Category

Latest News

- Congratulations for Successful show at 25th Xiamen International Stone Fair

- Join Us at the 2025 Xiamen Stone Fair

- Join Us at Marmomac 2024 in Verona Italy

- How To Choose The Good Diamond Wire for Your Cutting Works?

- Introducing Our New G123 Cobalt-Free Bond Diamond Wire!

- Why Diamond Wire Saw Is Becoming Popular?

- What's the Steps of Using Diamond Wire Saw Correctly

- How to Keep The Wire Saw Machine in Good Condition

- How To Choose Diamond Polishing Pads Correctly

- Diamond Wire for Granite Quarry And Processing Work

- Advantages of Wire Saw Machine Enhancing Efficiency and Precision

- Why Diamond Core Drill Bit Is Popular in Construction Industry?

- What’s The Applications of Diamond Wire Saws?

- Why Use A Diamond Saw Blade?

- WHY USE A DIAMOND WIRE SAW FOR CONCRETE CUTTING?

- What Are The Obvious Advantages of Diamond Wire Sawing

- What’s the applications of diamond wire saw: Granite, Marble or Concrete?

- How to use diamond wire saw correctly?

- What are Diamond Drill Bits used for?

- What is a diamond tool?

Related Products

7.2mm 8.5mm 9.0mm Plastic Coating Multi Diamond Wire Saw for Slabs Sawing

| Availability: | |

|---|---|

| Quantity: | |

-

ROC-MW75P

-

KEENTOOL

-

82029910

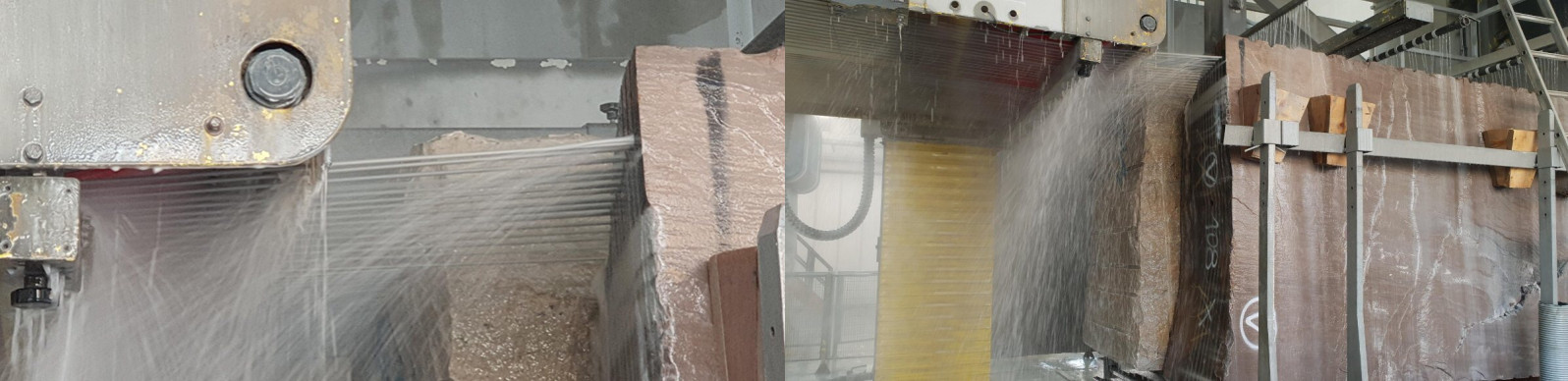

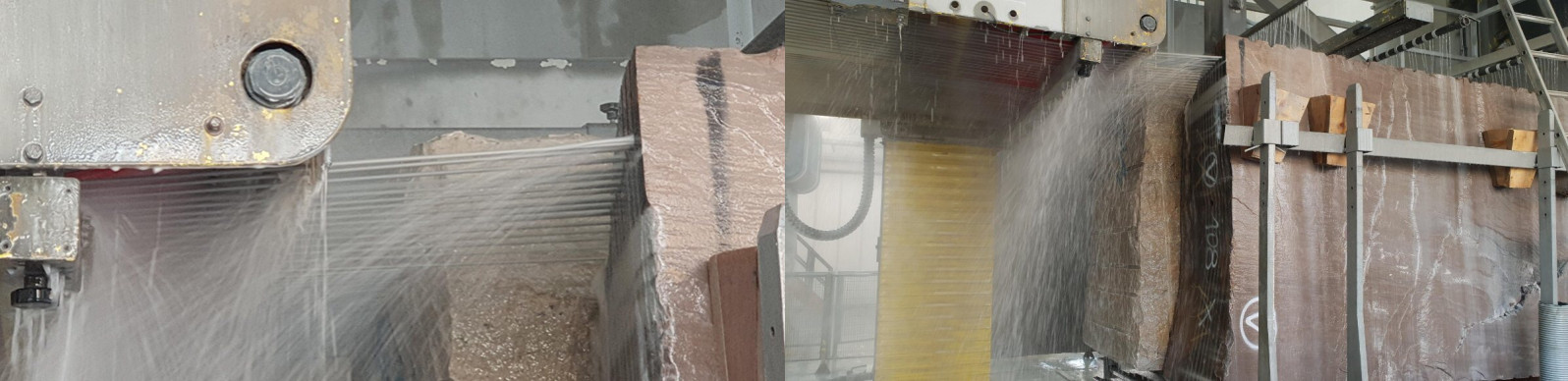

Multi diamond wire saw for slabs are injected with trasparent plastic and they contain 37 beads/m.

The advantages of using multi diamond wire saw is getting a decrease in the sawing costs and an improve productivities. The diamond wire saw is essentially composed of three main components:

●1.Steel cable with different diameter depending on the application.

●2.Sintered diamond beads.

Bond and diamond of multi diamond wire saw studied for the material to cut.

●3.Assembly typically in plastic

Protect the steel cable from the abrasive action of the stone and also absorbs the energy of the cutting friction of the beads against the stone.

APPLICATIONS | Art No | Specification (mm) | Beads/M | Reinforcement |

For all types of natural and artificial stone | ROC-MW75P | ¢7.4×7.0 | 37 | |

ROC-MW80P | ¢8.0×6.0 | 37 | BASF Plastic | |

ROC-MW90P | ¢8.0×6.0 | 37 | BASF Plastic | |

Cutting Material | Linear Speed (M/S) | Down Speed (CM/H) | Cutting Life (M2/M) | |

Soft | 50-100 | 16-40 | ||

Medium | 28-35 | 40-80 | 14-30 | |

Hard&Abrasive | 28-35 | 25-60 | 10-14 | |

SPECIFICATION OF BEADS | Out Diameter | Length of work layer (mm) | Bead Length | Manufacture Tech |

¢7.5 | 7.0 | 11 | Sintered | |

¢8.5 | 6.0 | 11 | Sintered | |

¢9.0 | 6.0 | 11 | Sintered |

Multi diamond wire saw for slabs are injected with trasparent plastic and they contain 37 beads/m.

The advantages of using multi diamond wire saw is getting a decrease in the sawing costs and an improve productivities. The diamond wire saw is essentially composed of three main components:

●1.Steel cable with different diameter depending on the application.

●2.Sintered diamond beads.

Bond and diamond of multi diamond wire saw studied for the material to cut.

●3.Assembly typically in plastic

Protect the steel cable from the abrasive action of the stone and also absorbs the energy of the cutting friction of the beads against the stone.

APPLICATIONS | Art No | Specification (mm) | Beads/M | Reinforcement |

For all types of natural and artificial stone | ROC-MW75P | ¢7.4×7.0 | 37 | |

ROC-MW80P | ¢8.0×6.0 | 37 | BASF Plastic | |

ROC-MW90P | ¢8.0×6.0 | 37 | BASF Plastic | |

Cutting Material | Linear Speed (M/S) | Down Speed (CM/H) | Cutting Life (M2/M) | |

Soft | 50-100 | 16-40 | ||

Medium | 28-35 | 40-80 | 14-30 | |

Hard&Abrasive | 28-35 | 25-60 | 10-14 | |

SPECIFICATION OF BEADS | Out Diameter | Length of work layer (mm) | Bead Length | Manufacture Tech |

¢7.5 | 7.0 | 11 | Sintered | |

¢8.5 | 6.0 | 11 | Sintered | |

¢9.0 | 6.0 | 11 | Sintered |