Product Category

Latest News

- Congratulations for Successful show at 25th Xiamen International Stone Fair

- Join Us at the 2025 Xiamen Stone Fair

- Join Us at Marmomac 2024 in Verona Italy

- How To Choose The Good Diamond Wire for Your Cutting Works?

- Introducing Our New G123 Cobalt-Free Bond Diamond Wire!

- Why Diamond Wire Saw Is Becoming Popular?

- What's the Steps of Using Diamond Wire Saw Correctly

- How to Keep The Wire Saw Machine in Good Condition

- How To Choose Diamond Polishing Pads Correctly

- Diamond Wire for Granite Quarry And Processing Work

- Advantages of Wire Saw Machine Enhancing Efficiency and Precision

- Why Diamond Core Drill Bit Is Popular in Construction Industry?

- What’s The Applications of Diamond Wire Saws?

- Why Use A Diamond Saw Blade?

- WHY USE A DIAMOND WIRE SAW FOR CONCRETE CUTTING?

- What Are The Obvious Advantages of Diamond Wire Sawing

- What’s the applications of diamond wire saw: Granite, Marble or Concrete?

- How to use diamond wire saw correctly?

- What are Diamond Drill Bits used for?

- What is a diamond tool?

Related Products

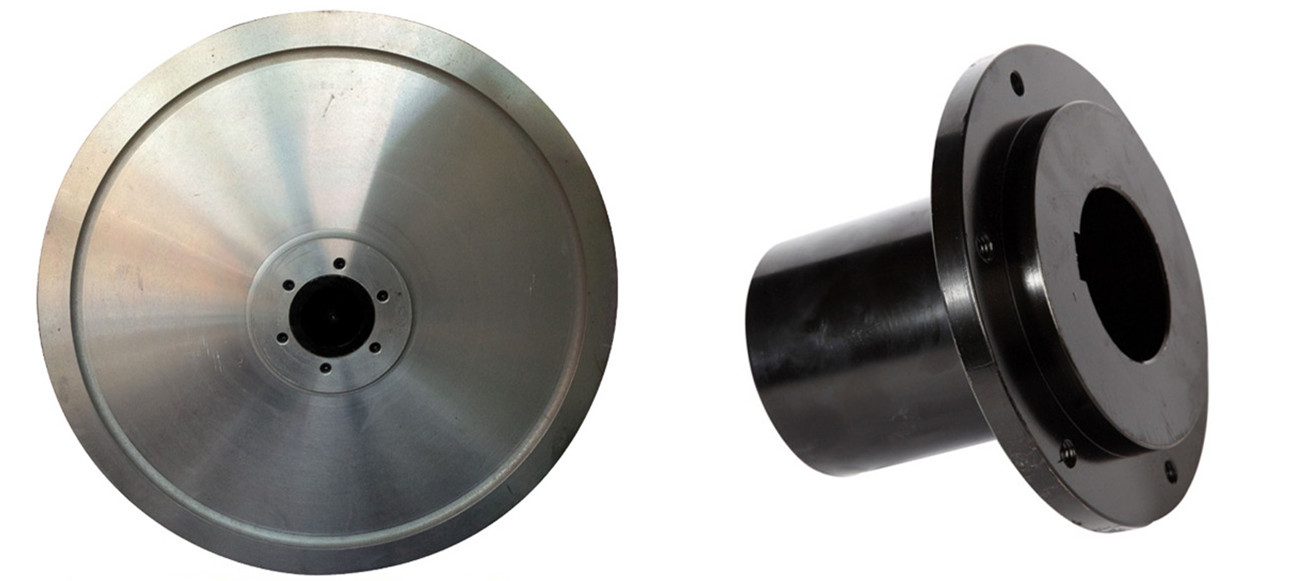

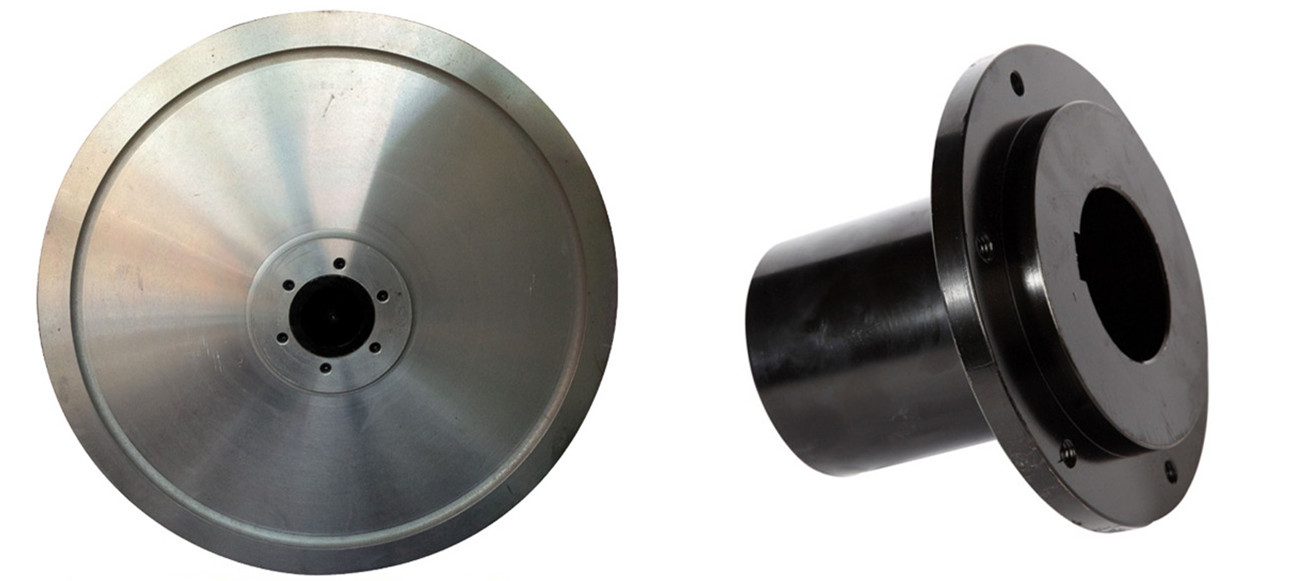

Flying Wheels And Driving Wheels for Wire Saw Machines

The Driving Wheel is the key power-transmitting component of a wire saw machine. It connects directly to the motor, rotating the diamond wire with consistent speed and torque for smooth, accurate cutting.The Driving Wheel is the key power-transmitting component of a wire saw machine. It connects directly to the motor, rotating the diamond wire with consistent speed and torque for smooth, accurate cutting.

| Diameter : | |

|---|---|

| Availability: | |

| Quantity: | |

-

200/300/350/380/400/500/600/800/1000

-

KEENTOOL

-

84669100

Flying Wheels and Driving Wheels for Wire Saw Machines

Precision Components for Stable and Efficient Diamond Wire Cutting

Our Flying Wheels and Driving Wheels are essential components engineered to ensure the optimal performance of your wire saw machines. Designed for stability, durability, and precision, these wheels play a critical role in maintaining smooth operation and maximizing cutting efficiency across a wide range of stone and construction materials.

Driving Wheel (Power Transmission Pulley)

The Driving Wheel serves as the core power component of the wire saw system. Directly connected to the motor, it drives the diamond wire with consistent speed and torque.

Manufactured from high-strength steel or aluminum alloy for maximum durability

Coated with wear-resistant rubber or polyurethane to enhance wire grip

Engineered with precision balancing and grooved surfaces to prevent slippage and reduce vibration

Delivers stable power transmission for accurate and efficient cutting

Flying Wheel (Guide Pulley)

The Flying Wheel, also known as the idler or guide pulley, is responsible for adjusting the wire path and maintaining proper tension throughout the cutting process.

Constructed from lightweight, high-strength materials for smooth rotation

Provides wire alignment and directional guidance without power input

Absorbs operational vibrations and reduces wear on the diamond wire

Mounted on adjustable arms or tensioners for fine-tuning of wire position and tension

Why Choose Our Wheels?

High precision machining for smooth, quiet operation

Improved wire life through optimized grip and tension control

Corrosion-resistant and built for long service life, even in demanding environments

Custom sizes and specifications available upon request

Enhance your wire saw performance with our high-quality Flying and Driving Wheels – engineered for precision, built for durability.

The driving wheel is an important part of wire saw machine for granite, marble, sandstone quarry.

Flying Wheels and Driving Wheels for Wire Saw Machines

Precision Components for Stable and Efficient Diamond Wire Cutting

Our Flying Wheels and Driving Wheels are essential components engineered to ensure the optimal performance of your wire saw machines. Designed for stability, durability, and precision, these wheels play a critical role in maintaining smooth operation and maximizing cutting efficiency across a wide range of stone and construction materials.

Driving Wheel (Power Transmission Pulley)

The Driving Wheel serves as the core power component of the wire saw system. Directly connected to the motor, it drives the diamond wire with consistent speed and torque.

Manufactured from high-strength steel or aluminum alloy for maximum durability

Coated with wear-resistant rubber or polyurethane to enhance wire grip

Engineered with precision balancing and grooved surfaces to prevent slippage and reduce vibration

Delivers stable power transmission for accurate and efficient cutting

Flying Wheel (Guide Pulley)

The Flying Wheel, also known as the idler or guide pulley, is responsible for adjusting the wire path and maintaining proper tension throughout the cutting process.

Constructed from lightweight, high-strength materials for smooth rotation

Provides wire alignment and directional guidance without power input

Absorbs operational vibrations and reduces wear on the diamond wire

Mounted on adjustable arms or tensioners for fine-tuning of wire position and tension

Why Choose Our Wheels?

High precision machining for smooth, quiet operation

Improved wire life through optimized grip and tension control

Corrosion-resistant and built for long service life, even in demanding environments

Custom sizes and specifications available upon request

Enhance your wire saw performance with our high-quality Flying and Driving Wheels – engineered for precision, built for durability.

The driving wheel is an important part of wire saw machine for granite, marble, sandstone quarry.