Product Category

Latest News

- Congratulations for Successful show at 25th Xiamen International Stone Fair

- Join Us at the 2025 Xiamen Stone Fair

- Join Us at Marmomac 2024 in Verona Italy

- How To Choose The Good Diamond Wire for Your Cutting Works?

- Introducing Our New G123 Cobalt-Free Bond Diamond Wire!

- Why Diamond Wire Saw Is Becoming Popular?

- What's the Steps of Using Diamond Wire Saw Correctly

- How to Keep The Wire Saw Machine in Good Condition

- How To Choose Diamond Polishing Pads Correctly

- Diamond Wire for Granite Quarry And Processing Work

- Advantages of Wire Saw Machine Enhancing Efficiency and Precision

- Why Diamond Core Drill Bit Is Popular in Construction Industry?

- What’s The Applications of Diamond Wire Saws?

- Why Use A Diamond Saw Blade?

- WHY USE A DIAMOND WIRE SAW FOR CONCRETE CUTTING?

- What Are The Obvious Advantages of Diamond Wire Sawing

- What’s the applications of diamond wire saw: Granite, Marble or Concrete?

- How to use diamond wire saw correctly?

- What are Diamond Drill Bits used for?

- What is a diamond tool?

Related Products

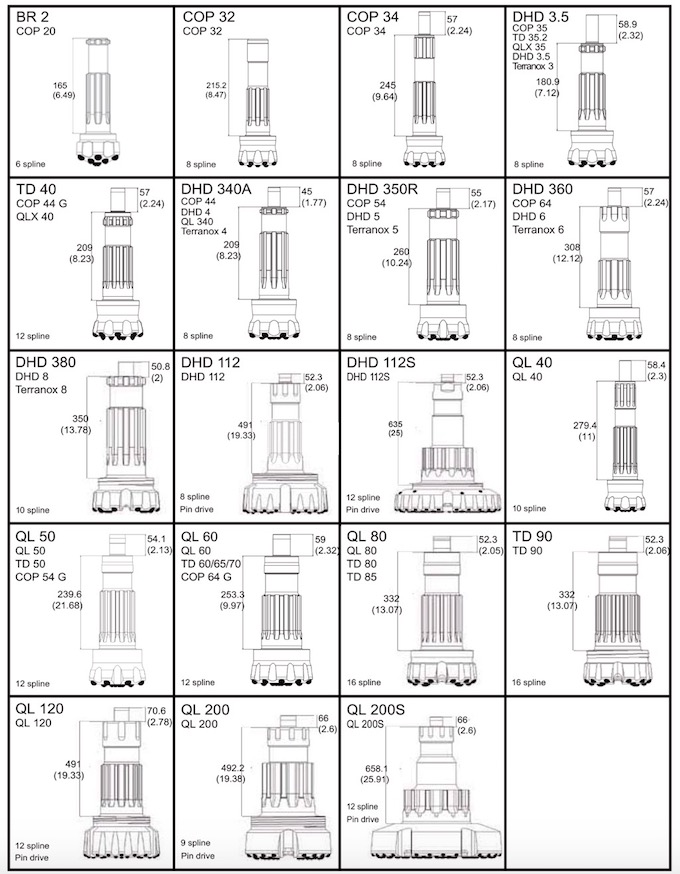

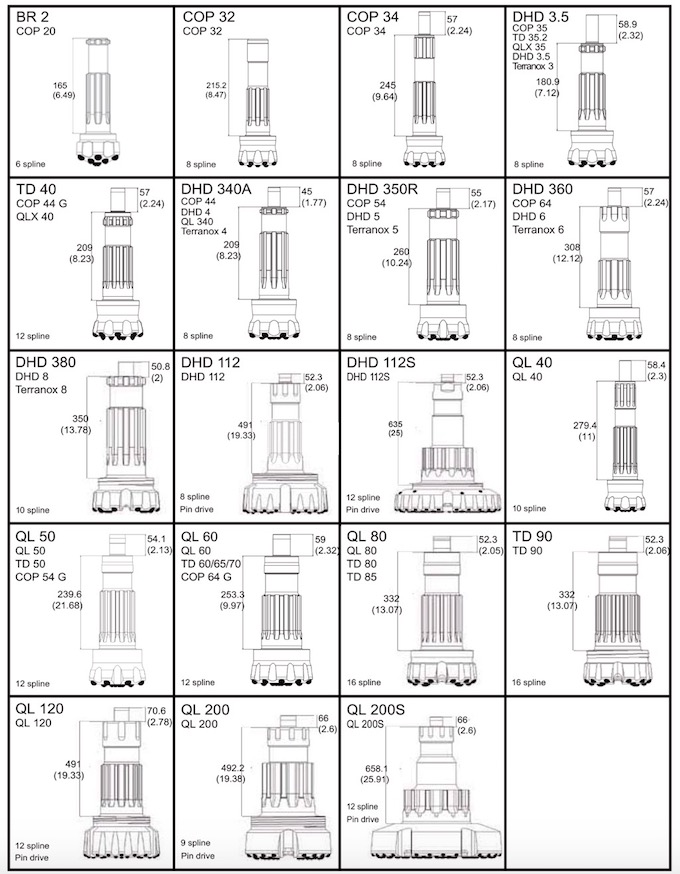

CIR65 CIR90 DTH Drill Bits for DTH Drill Machines

| Availability: | |

|---|---|

| Quantity: | |

-

CIR65

-

KEENTOOL

-

KT-CIR65

KEENTEC supplies a wide range of DTH drill bits to match all conceivable rock perforation applications. Each unit of DTH rock drill bit is made from premium quality alloy steel, and has been precision manufactured with a perfect body, heat treated to the engineered hardness, given surface compression for fatigue resistance, and fitted with precision buttons manufactured in-house.

These are designed for professional application of all types of rock perforation with big varieties of hardness and conditions. The diamond core drill bit drilling life or productivity and penetration rate are the most important criteria in selecting the proper bit for a particular application.

The DTH bit with concave face and ballistic buttons is mainly introduced for soft to medium hard non abrasive rock, convex front and semi-spherical buttons is recommended for soft to medium hard abrasive rock; bit with flat front and semi-spherical buttons are recommended for hard and abrasive rock. DTH bits for low, middle and high air pressure working applications are available as per request.

1 drill bits be packed in carton with crash-proof foam

Sample lead time: In 3 working days.

Bulk Goods delivery time: In 30 days

Features

Proprietary carbide ensures high quality and performance

Carbide grade options for long life in challenging applications

Face designs to maximize penetration rate and tool life

KEENTEC supplies a wide range of DTH drill bits to match all conceivable rock perforation applications. Each unit of DTH rock drill bit is made from premium quality alloy steel, and has been precision manufactured with a perfect body, heat treated to the engineered hardness, given surface compression for fatigue resistance, and fitted with precision buttons manufactured in-house.

These are designed for professional application of all types of rock perforation with big varieties of hardness and conditions. The diamond core drill bit drilling life or productivity and penetration rate are the most important criteria in selecting the proper bit for a particular application.

The DTH bit with concave face and ballistic buttons is mainly introduced for soft to medium hard non abrasive rock, convex front and semi-spherical buttons is recommended for soft to medium hard abrasive rock; bit with flat front and semi-spherical buttons are recommended for hard and abrasive rock. DTH bits for low, middle and high air pressure working applications are available as per request.

1 drill bits be packed in carton with crash-proof foam

Sample lead time: In 3 working days.

Bulk Goods delivery time: In 30 days

Features

Proprietary carbide ensures high quality and performance

Carbide grade options for long life in challenging applications

Face designs to maximize penetration rate and tool life